Sign up for the most productive news and knowledge about herbal gases. Follow the topics you need and receive emails.

The construction of royal Dutch Shell plc’s multimillion-dollar ethanol cracker in western Pennsylvania is 70%, while the 98-mile pipeline formula that would force installation is complete by 95%, a corporate executive said Tuesday, noting that the Covid-19 pandemic has confused the project.

“All primary appliances are in service, all modules that have been built internationally in the US are in service. But it’s not the first time And they’ve been placed on site,” said Hilary Mercer, vice president of Pennsylvania Chemicals for Shell Polymers. “It remains to bring those elements in combination, to weld everything in combination and pull the electrical cables and tool cables to allow us to animate the installation. “

The facility, the first of its kind to be built in the United States off the Gulf Coast in more than 20 years, was legal in 2016 to take advantage of the merits of Appalachian ethanol materials and a strong polyethylene market in the region. and site preparation began long before that. The facility is under structure in Beaver County, about 30 miles northwest of Pittsburgh, and will be largely self-sufficient with its own gas-based herbal power plant and water remedy facility.

Some of the application systems are already in service and the plant is expected to start early next year, Mercer said in comments at the Shale Insight virtual conference.

Shell was forced to temporarily suspend the allocation structure before this year in the midst of the coronavirus outbreak as a precautionary measure to protect the force from paintings and paintings from local networks given the number of others at the site. When the paintings stopped in March, Mercer said there were about 8,000 other people of the pictorial force.

Construction has resumed, but it is unclear when the facility will enter the advertising service. Even when the paintings are completed, commissioning activities will be long, Mercer said. While Shell sometimes does not talk about his timetable for such projects, Mercer said the pandemic had tarnished the calendar.

“We had to convince ourselves that we could remain a paint force for more than 6,000 people running and running constantly during the ‘pandemic’ before we can begin to think about what it would look like in terms of the overall timetable. “said. ” Now we have reached a point where we can make paintings and paintings of this number safely. Lately we’ve been looking at our general schedule while I’m talking. “

For the Falcon Ethane pipeline, a two-branch formula that will collect ethane from service processing and division in Ohio, Pennsylvania and West Virginia, the last piece of pipe placed on September 10, the formula will have the ability to ship 100,000 b/d. from ethanol to cracker as a component of agreements of origin with a dozen Appalachian producers.

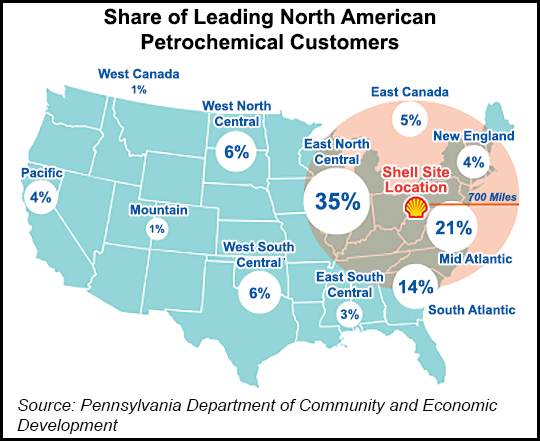

The facility is designed to produce 1. 5 million metric tons according to the year (mmty) of ethylene and 1. 6 mmty of polyethylene, which are key parts for plastics. Approximately 70% of North America’s polyethylene market is within a 700-mile radius along the Ohio River, according to Shell.

Download the PDF edition