Change Language:

With SHL Medical

Combination products have moved away from traditional, resource-intensive designs toward more efficient platform-based modular manufacturing. SHL Medical’s DAI® generation was one of the first auto-injectors to explore a platform design trend with a recognizable commercial design for diseases. Since then, modularization has become even more scalable, as evidenced by SHL Medical’s Molly® auto-injector, which has supported the approval of at least 17 separate combination product projects in disease areas.

With pharma companies striving to address a widening range of diseases through novel drugs and biosimilars in autoinjectors, efficiency is an even more critical competitive edge for medical device makers.

Christian Walter, global head of operations engineering at SHL Medical, says the company has been expanding and accelerating its production operations for several years by leveraging Industry 4. 0 technologies such as end-to-end procedure digitization, internal automation, and broad diversity. of technologies. Data research for scalable production.

To facilitate this expansion, one step SHL Medical is taking is to apply complex simulation strategies and equipment to create virtual models of its processes, production lines, machines, and supply chains.

“Simulation is a challenging generation that is transforming the way we compare and optimize complex processes,” he says. “It allows us to dive into individual processes and understand how they interact. Running simulation events in a virtual environment gives brands the data they need. “Make informed decisions about your operations.

Walter adds that simulation technologies are preferentially suitable for the production of auto-injectors, as they involve complex processes, well-defined chains, and many formulation limitations.

SHL Medical, as a provider of end-to-end answers, has a committed team of plant simulation engineers, who use complex modeling techniques to simulate the production processes of an autoinjector. The team uses undeniable static models and highly incorporated dynamic simulation. modeling, depending on the needs of the simulation task.

According to Walter, static modeling is an undeniable but effective way to create multiple scenarios and rule out insufficient solutions. “For example, we can easily assess production quantities, yields, and area constraints,” he says. “With the right knowledge and information formulas, a plant simulation engineer can temporarily identify various production parameters, medium and worst-case scenarios, and discover the ideal configuration. “

Simulation modeling is a more visual and complex strategy in which engineers use specialized software to create complicated simulations of discrete events. These animated representations of complex systems enable dynamic interactions between various processes and subsystems.

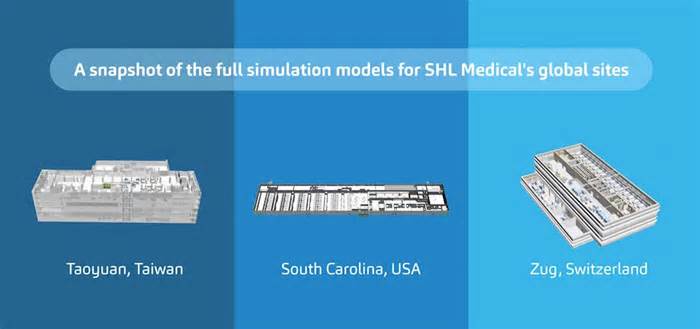

SHL Medical has implemented simulation modeling extensively, creating modularized three-dimensional models of its entire production infrastructure. This enables the simulation of discrete and continuous production processes in your global facilities, production processes, flows, and automated machines.

The highly demand-driven procedure of managing production capacities across multiple autoinjector platforms demands continuous optimization of curtain flow, resource utilization and other dimensions.

For pharmaceutical corporations that are constantly reducing time to market, the biggest advantages of simulation are faster delivery times for device manufacturers. In the case of SHL Medical, both new and existing projects benefit from the efforts of the plant simulation team to dynamically analyze opportunities to improve and optimize procedures in real time.

“With an internal control system, any SHL employee can request optimization proposals for production procedures or fast workflows,” says Walter. “And since we have a very varied procedural landscape that uses production machines of other degrees of automation, analyzing the interactions between people, machines and the production organization can bring wonderful benefits in maximizing operational efficiency. »

Plant simulation is imperative for modeling and optimization. For example, in a what-if scenario, initial production parts are moved from the curtain distribution station to a buffer zone before being assembled into the fully automated assembly device (FAAM). It evaluates the trade-off between a smaller, more profitable workforce and a larger workforce in terms of curtain replacement. SHL Medical uses this granular research to identify the optimal balance in terms of potency in various scenarios.

As the number of patients relying on auto-injectors for healing continues to increase, SHL Medical has also found simulation to be useful on a much larger scale.

The company is currently undertaking a global expansion, with new production facilities in the United States and Switzerland. These sites will bring production lines closer to the headquarters of many leading pharmaceutical and biotechnology corporations and, in combination with SHL Medical’s existing facilities in Taiwan. , will include the true essence of 24/7 operations.

“The simulation team has modelled the operation of each factory, from the process flow to material handling to machine interaction,” Walter says. “Our aim is to implement equivalent operating models across all sites, whereas there are significant differences in terms of layout of each facility. This means our simulation models – whether for the machines, shop floors, or spaces – can be leveraged across all sites.

“It’s like stepping on the accelerator of SHL Medical’s expansion because we wouldn’t possibly have to spend time and resources planning the operations of each new facility from scratch. “

While mass customization is expected to be the next trend in auto-injectors, simulation appears to be a component of achieving the production flexibility and scalability needed to meet the desires of pharmaceutical corporations and patients.

To learn more about SHL Medical’s Molly® Modular Platform Autoinjector, download the document below.